2016 Boiler Rebuild for the SP&S 700

Superheater Pipe Sponsorship Fundraiser

The superheaters on the SP&S 700 are old, worn out by the caustic environment and the constant temperature swings within the flue tubes, and they need to be replaced. You can help keep the "First Lady of the Northwest" in service for many years to come by sponsoring one or more of her new superheaters. All donations will be used for the inspection and rebuild of the SP&S 700, and as always all donations are 100% tax deductible.

Instructions:

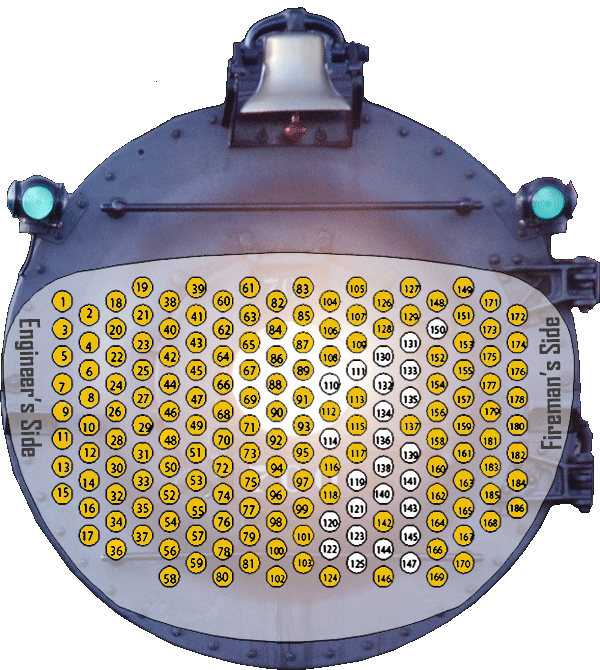

- Select the superheater number(s) you'd like to sponsor by looking at the tube sheet diagram at left and checking the list of sponsors below to find available units.

- To pay online with a credit card, debit card, or PayPal account, first click the big red button below, which opens up PayPal on a new tab. Next enter the amount you'd like to donate: $275 for your first superheater, or $200 for each subsequent one (including if your first was in any prior order). Now log in to PayPal (or near where it says "Don't have a PayPal account?" on the lower right click the "Continue" link and enter all your information). Then on the review your donation screen, find the text that says "Unit# and Name to Display on Website," click it, and in the box that appears enter the superheater number(s) you'd like to sponsor and the name(s) you'd like to have appear in the donor list below .

- You can also save us PayPal's 2.2% service charges by sending in a check. Just print out this form, fill it out, and mail it in along with your check. It may be old school technology, but like the 700, it works better than some of the new ways!

| Superheater Sponsors | ||

|---|---|---|

|

|

|

What is a superheater?

The boiler of the SP&S 700 has 186 flue tubes of 3.75" diameter and 54 more of 2.00" diameter. These 21' tubes carry the hot exhaust fumes from the firebox to the smokebox. Nestled within each of the larger tubes is another pair of pipes connected at the firebox end by a "U"-shaped return casting. This inner assembly is called a superheater. Within the smokebox, one of the pipes from each superheater is joined in a manifold called the superheater header while the other pipe leads to a similar manifold at the throttle box.

What does a superheater do?

The short answer is that superheaters convert "wet" steam into "dry" steam. For a better understanding, let's follow the steam in an operating engine. We've already mentioned that the flue tubes channel the hot exhaust fumes from the firebox to the smokebox. As they do so, they transfer heat from fumes to the boiler water. As the water gets hotter and hotter, it eventually boils, creating "wet" steam and raising the pressure. Now when the engineer opens the throttle, this wet steam leaves the boiler, travels down the dry pipe, and enters the superheater header in the smokebox. The path of the steam there divides, leading through the 186 individual superheaters. While passing through the superheaters, the wet steam's temperature is raised several hundred degrees and it becomes known as "dry" steam because it is no longer on the verge of condensing into water. The dry steam next exits the superheater, passes through the throttle body and enters the steam chests and cylinders, where it provides the motive force of the locomotive. Dry steam is superior to wet steam for powering the locomotive because it provides higher thermal efficiency and is less likely to condense within the piping and cylinders.